inactio machine models

The perfect promotional item for your customers!

From design to finished model – everything from a single source

Why are scale models the perfect advertising medium?

Your customer is reminded of your brand and product every time he looks at the scale model.

The models are small and lightweight - ideal for worldwide shipping.

It is perfect as a gift, looks good on the desk / bookcase and is a noble collector's item.

We tailor each offer to your individual needs and expectations:

- Appropriate design of the structure

- Introduction to the production process

- Regular production report and prompt responses

- We accompany you through the entire process – from the agreement to the delivery of the product – wherever your destination may be.

1. The project description

We discuss together the details of your project, such as:

- model name

- model scale

- materials

- quality grade

- position

- distinctive characteristics

- quantum

- packaging details

- and so far

2. Product drawings or photos

You provide us with detailed drawings/photos, dimensions and equipment data for your product. This is very important for a high quality scale model project. On the basis of available information, we prepare a detailed offer for you, based on the information provided by you, e.g. tool quantity, 3D design costs, tool costs, unit costs, etc..

A complete information base is an important first step towards a high-quality model.

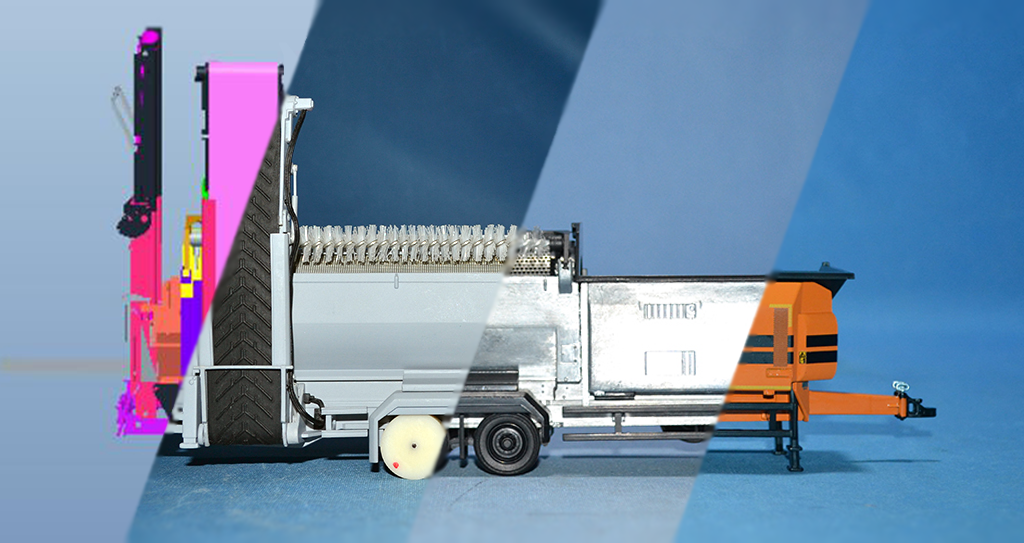

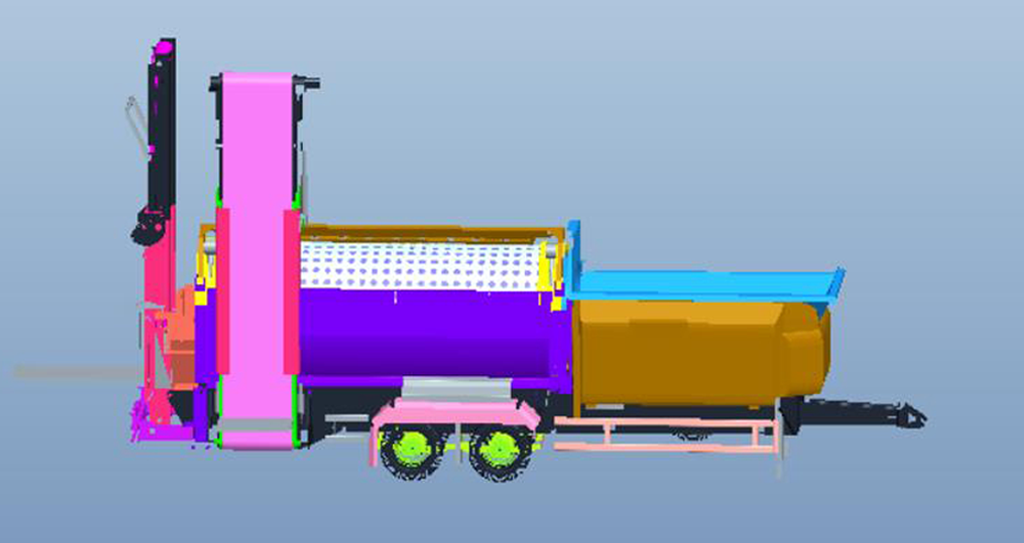

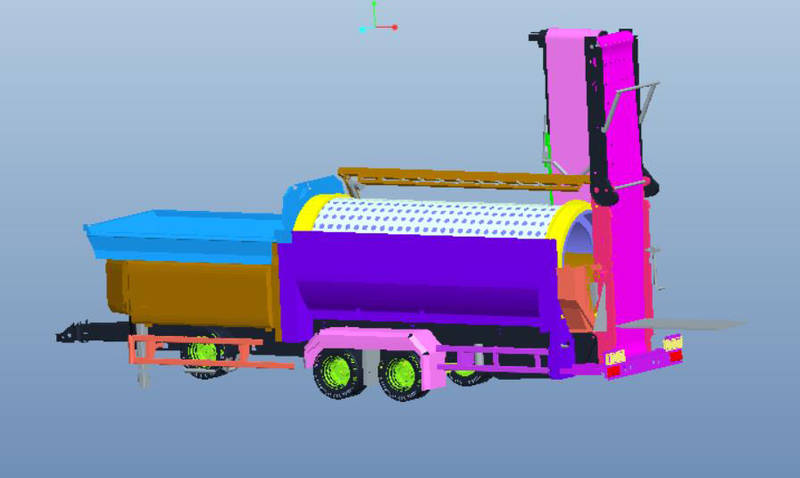

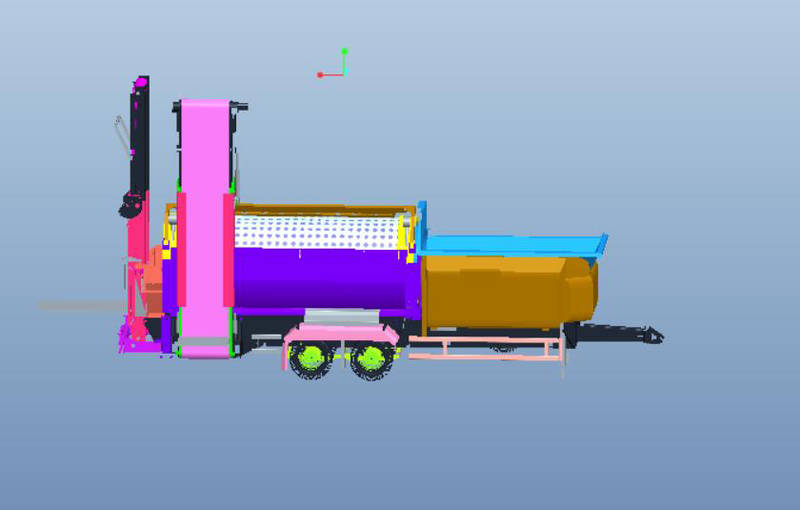

3. The simplified 3D-Design

The model is now created as a 3D drawing (unallowed, functional replica not possible) based on the supplied photos, your simplified 3D drawings and descriptions to show you all needed product details and functions of the model. The production of the 3D drawing takes about 25-30 days and will then be sent to you for adjustments and approval.

The 3D model is an important second step for the high quality of the final model.

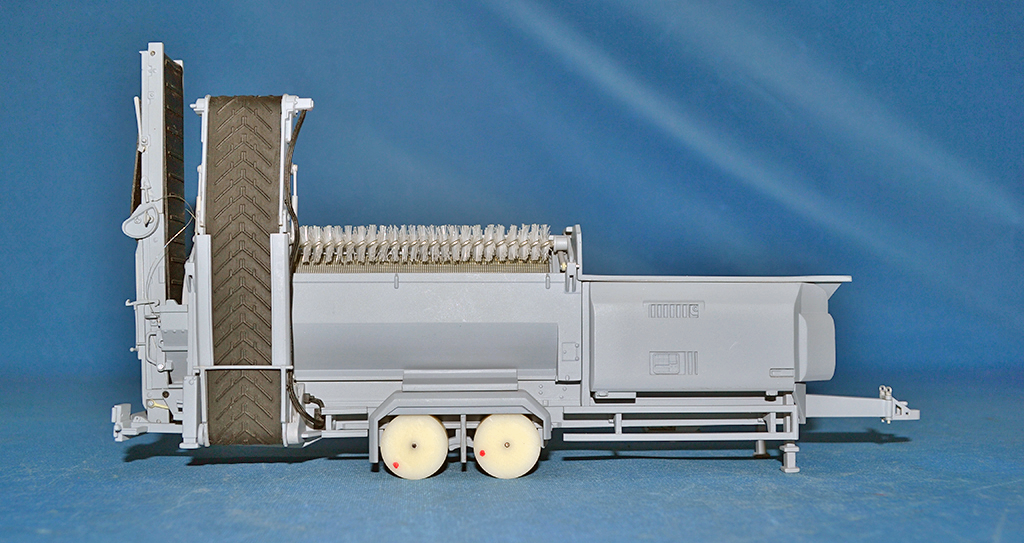

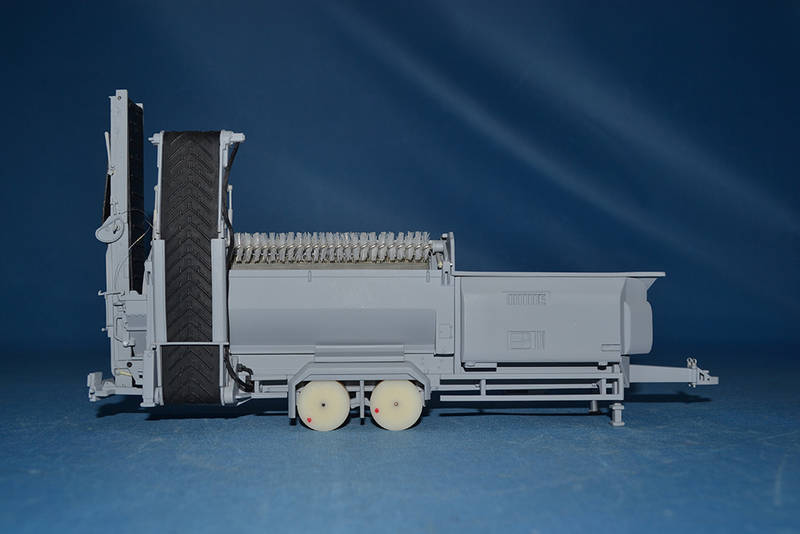

4. The production of the prototype

Based on the 3D drawing taken from them, the first prototype of the model is then handmade from plastic.

5. Mould design, tool- & mould making:

After the 3D drawing and prototype have been confirmed, we move on to mould design, tool making and mould making.

This step takes about 45 days, depending on the desired level of detail and the desired quality of the model.

The best merchandise item is always your own product!

Scale it to a “giveaway size” and your customer will be reminded of your brand and product every time he sees it!

- We are always striving to produce a scale model in high quality with realistic and accurately reproduced features and details – a collector’s item, a management gift, a purchased product. A gift that you will give away with pride and value to the recipient.

- The best effect is achieved when a scale model is produced at the same time as the real product is introduced. All customer and product information is always treated confidentially.

We also support you in storage, distribution, logistics and shipping worldwide!

6. First sample model & modifications

After production of the moulds, the first sample model is produced within a few days. Our engineering team then checks whether all the desired details are actually reproduced and whether all component parts and details meet your design and production requirements. After the internal confirmation, the sample is presented to you for approval. Based on your feedback, the refined 2nd shot pattern is then created.

7. Second sample model & packaging

We are now producing the second sample model with complete painting and packaging. As soon as everything meets your expectations, a final pre-series sample is produced after approval.

8. Mass production

Once the pre-series sample and packaging have been confirmed, mass production begins. The mass production process includes the following steps:

- Diecasting & injection moulding

- surface treatment

- paintwork

- pad printing

- final assembly

- Quality control and

- package

9. Final inspection & dispatch of the model

After mass production, the models are finally checked and shipped to the desired place of delivery. According to your wishes by train, ship or air freight, to any place in the world.

We also support you in storage, distribution, logistics and shipping worldwide.

Please do not hesitate to contact us:

Address

inactio solutions GmbH

Andreasstr. 48

D-47441 Moers